|

| December 22, 2020 | Volume 16 Issue 49 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Bentley Blower reborn after 90 years for special limited run

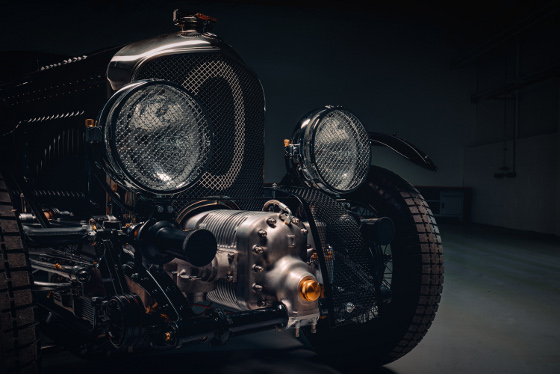

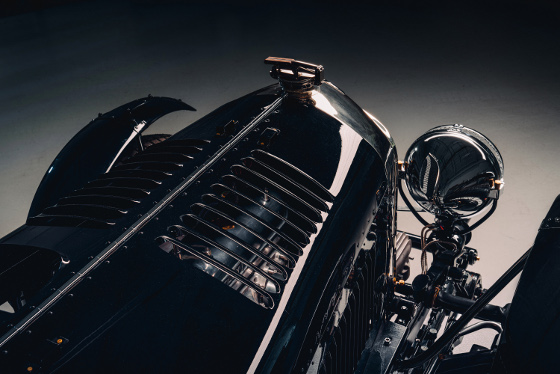

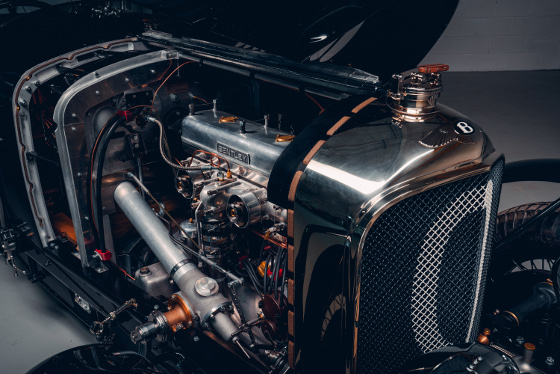

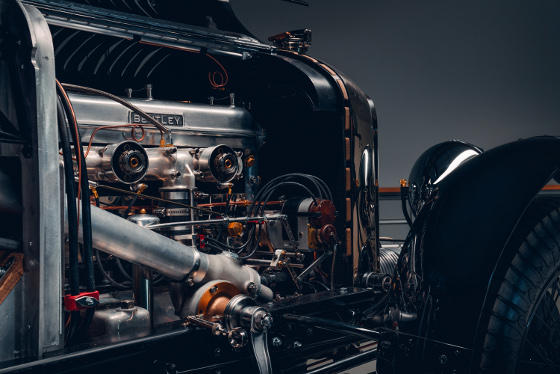

New Bentley Blower Car Zero. [All images courtesy Bentley Motors]

Everything old is new again, they say. That certainly holds true at Bentley Motors, where a dedicated design and production team has spent more than 40,000 hours to create nearly 2,000 individually designed and handcrafted parts to complete Car Zero, the working prototype for its exclusive 12-unit Blower Continuation Series. All the final cars will be crafted from the design drawings and tooling jigs used for the original four Blowers built and raced by Sir Henry 'Tim' Birkin in 1929 and 1930 (officially debuted 1929).

Bentley's own Team Car #2 was used as the master model for the Continuation Series, with every single component laser-scanned as part of the wheels-up re-creation. Originally, 55 supercharged Blowers in total were produced.

After all that scanning, 1,846 individual parts were designed and handcrafted to fashion the new Blower. Bentley says 230 of those parts are actually assemblies (one of which is the engine), taking the total part count to several thousand when fixings and interior trim parts are included. Each of these parts and assemblies was created by a project team of Bentley Mulliner engineers, craftspeople, and technicians working together with a number of British specialists and suppliers.

The Blower Continuation Series is the first customer-facing project delivered by the new Bentley Mulliner Classic portfolio, one of three new divisions of Mulliner.

The Blower Car Zero is the dedicated test and development prototype built in advance of the 12 customer cars. It will be subjected to months of durability and performance testing before the final cars are built. Final performance numbers will be revealed after all testing is complete.

The first step in creating Car Zero was an extensive analysis of the original design drawings and drafts that were referenced in the creation of the original Blower Team Car, together with archived period photographs of Blower cars. Following a piece-by-piece disassembly of the #2 Team Car owned by Bentley (which the company says is likely the most valuable Bentley in the world) and an exceptionally precise laser scanning of the frame and its components, a complete digital CAD model of the Blower was created.

From there, a team of artisan specialists was recruited to start manufacturing the components for Bentley Mulliner to bring together. Manufacturing methods true to the 1920s were used to create many of the parts.

The chassis was created in heavy-gauge steel. It was hand-formed and hot-riveted by the specialists at Israel Newton & Sons Ltd. This 200-year old company, based near Derby, UK, traditionally makes boilers for steam locomotives and traction engines. Leaf springs and shackles were made to original specifications by Jones Springs Ltd, a specialist in the West Midlands, UK, with nearly 75 years of experience and a history that started in a blacksmith's forge. The Blower's iconic headlamps were reborn by Vintage Headlamp Restoration International Ltd in Sheffield, a father-and-son team that is world-renowned for their silversmithing.

A new ash frame was created by Lomax Coachbuilders (based in Ludlow) and underwent the final stages of carpentry with Mulliner's team of experts, including the application of 25 m of highly specialized Rexine material (artificial leather) used to wrap the body. The gloss-black bodywork is paired with Oxblood red Bridge of Weir leather and matching trim. As per the originals, the seats are stuffed with a total of 10 kg of natural horsehair.

Under the hood is an interesting mix of old and new. The 4 1/2-liter engine features aluminum pistons, an overhead camshaft, four valves per cylinder, a magnesium crankcase, and twin spark ignition. It also sports a newly machined Amherst Villiers roots-type supercharger ("aka blower") that has been added in front of the radiator, just like the original, which boasted 177 hp. It is driven straight from the crankshaft.

While the first engine was being assembled, work was also underway to convert an engine testbed at Bentley's Crewe headquarters to accept the nearly 100-year old engine design. The engine test facility has been at Bentley since the factory was built in 1938, and the cells were originally used to run and power-test Merlin V12 aero engines produced by the factory for the Spitfire and Hurricane fighters of WWII.

Bentley says preparing the test bed involved making a replica Blower front chassis to hold the engine, which could then be mounted to the computer-controlled engine dynamometer. A new software version to measure and control the engine was also written and tested, which allowed Bentley's engineers to monitor and run the engine to precise parameters. As the Blower powertrain is considerably different in size and shape to Bentley's modern production engines, a number of the original Merlin testbed fixtures, which were still in storage at Bentley, were used to adapt the testbed to accommodate these special engines.

The new Bentley Blower Car Zero (foreground) with the original #2 Team Car owned by Bentley.

With the Car Zero build complete, the real-world testing begins. Sessions of gradually increasing duration and speed will check functionality and durability. The test program is designed to achieve the equivalent of 35,000 km of real-world driving across 8,000 km of track driving, and simulates the undertaking of famous rallies such as Peking to Paris and Mille Miglia.

What will this blast from the past cost? Slash Gear reports it will set you back just shy of $2 million. Whew! Reliving the past is very expensive.

Sources: Bentley Motors, Slash Gear

Published December 2020

Rate this article

View our terms of use and privacy policy